Realize maximum production and revenue with the DPS900 Piling System—the industry’s first aftermarket, land-based, 3D piling system for the mixed fleet operator.

Realize maximum production and revenue with the DPS900 Piling System—the industry’s first aftermarket, land-based, 3D piling system for the mixed fleet operator.

| Download Brochure | Download Configuration Sheet |

Get a quick return on your investment – DPS900 can pay for itself in just four months by:

Get a quick return on your investment – DPS900 can pay for itself in just four months by:

AUTOMATE BLOW COUNT RECORDING

- Reduce human error and generate accurate reports to maximize machine use.

POSITION PILES ACCURATELY WITHOUT STAKES

- Piles are in the right place the first time to minimize costly rework.

REDUCE NAVIGATION TIME BETWEEN PILES

- Small increases in production add up to significantly more piling time per day so you can make more money.

INCREASE SITE SAFETY

- Less people around the machines can reduce risk.

.

RUGGED HARDWARE

RUGGED HARDWARE

BUSINESS CENTER – HCE

Optimized drill plans. Optimal results.

Rapidly create optmized 3D drilling and piling plans with the Business Center – HCE Drill and Pile Manager module, then generate comprehensive quality and production reports.

With Business Center – HCE and DPS900, more profits are at your fingertips.

SMART OFFICE SOFTWARE

TRIMBLE ANTENNAS AND RECEIVERS

TRIMBLE ANTENNAS AND RECEIVERS

Smart and tough. A great combination.

Work in tough environments, at long ranges, with centimeter accurate 3D positioning seconds after start up with proven Trimble antennas and receivers. You get increased productivity and reduced downtime on the job. And Trimble equipment is certified tough enough to withstand the shock and vibration of drilling machines.

TRIMBLE SENSORS FOR CONTROL

Maximize efficiency. Minimize rework.

Trimble sensors give you mast tilt and drill depth control with auto-stop on the target elevation for effective blasting. You can even get information about hole condition while drilling.

TRIMBLE SITE TABLET

Keep your machines drilling. Not sitting.

Your machines can be up and running 24/7 with the rugged and fully connected Trimble Site Tablet and DPS900 software.

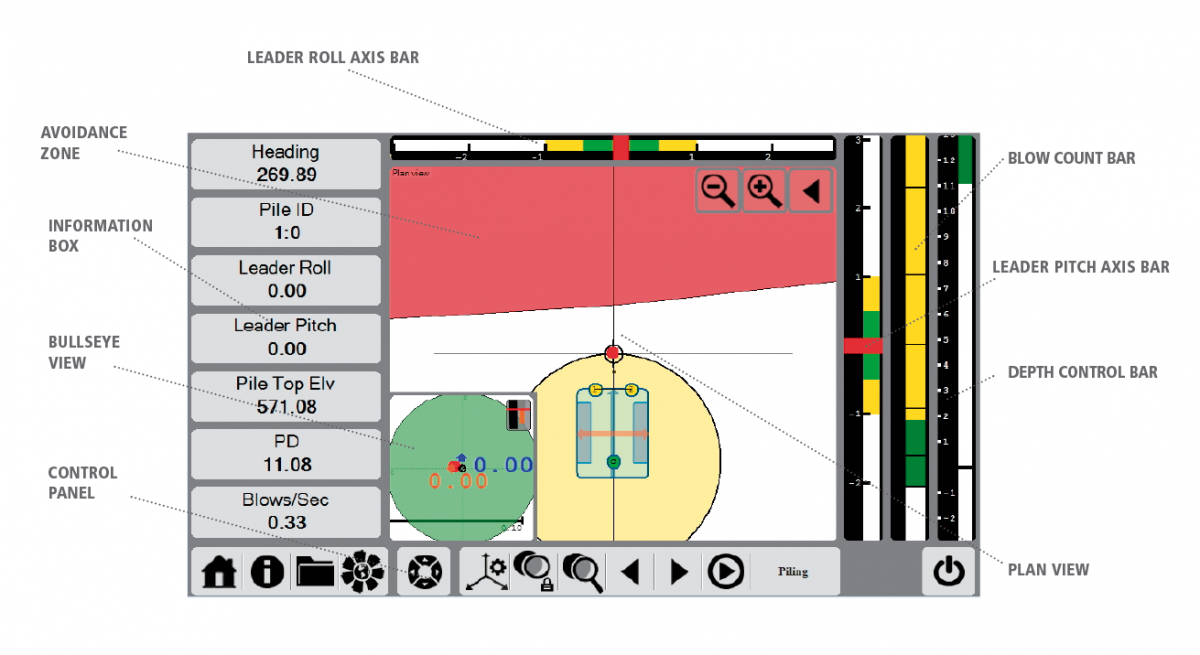

The easy-to-read touch screen makes navigating to the hole, and adjusting the orientation and angle of the guide simple and quick. Start drilling. Drill to design. Stop drilling.

It’s really that easy.

THE DPS900 SYSTEM IS IDEAL FOR:

THE DPS900 SYSTEM IS IDEAL FOR:

- Structural foundations

- Retaining walls

- Coffer dams

- Solar or wind farm installations

With delivery, installation, training and support from your SITECH® dealer, you’re guaranteed peace of mind. With a ROI analysis. Local support, service and expertise are just a phone call away.

With delivery, installation, training and support from your SITECH® dealer, you’re guaranteed peace of mind. With a ROI analysis. Local support, service and expertise are just a phone call away.

ON THE MACHINE

- Trimble antennas and receivers

- Trimble Zephyr 2 Rugged Antenna

- Trimble SPS855 GNSS Modular Receiver

- Trimble SPS555H GNSS Heading Add-on Modular Receiver

- Trimble CAN sensor system

- Trimble JB900 Junction Box – provides clean power, CAN, USB and Ethernet communications

- I/O Box – provides interface for blow count reporting

- Trimble TS900 Tilt Sensor – monitors machine leader for tilt in the pitch and roll axis of the machine

- Hammer elevation control sensors – options are available for most common installation types

- Telescopic mast/leader sensor – monitors leader extension on machines with an extendable mast

- M30 Proximity switch – monitors blow counting of the hammer

IN THE CAB

- DPS900 is engineered specifically for piling operations

- Large icons, a streamlined workflow and a screen that’s easy to read, even in bright sunlight

- Easy-to-read touch screen

IN THE OFFICE

- Business Center – HCE rapidly creates optimized 3D piling plans using the Business Center – HCE Drill and Pile Manager module

- Store the pile plans in the cloud for on-site retrieval by DPS900. No more driving out to the site to make updates

- DPS900 gathers the field data so Business Center – HCE can run accurate quality, production, utilization and consumables reports